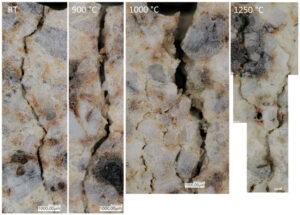

Thermal shock resistance: The key to refractory longevity

In high-temperature industrial processes, refractory materials are the silent backbone of operations. Whether in glass furnaces, steel ladles, cement kilns, non-ferrous metallurgy, or petrochemical units,